Gold mining in South Africa is a complex and historically significant industry. Known for hosting the Witwatersrand Basin, which has produced over 40% of the world’s mined gold, South Africa uses both underground and open-pit mining methods to extract this valuable resource.

1. The Witwatersrand Basin – The Heart of Gold Mining

The Witwatersrand Basin in Gauteng province is the core of South Africa’s gold production. This ancient sedimentary basin contains gold reefs trapped between layers of hard rock, making deep-level underground mining the primary method of extraction.

Key features:

- Gold deposits lie at depths of up to 4 kilometers

- Reefs are thin but highly concentrated

- Mining operations can extend over large horizontal distances

2. Underground Mining – The Main Method

Most gold in South Africa is extracted through underground mining, due to the depth of the ore bodies. The process includes:

Step 1: Shaft Sinking

Vertical or angled shafts are dug to access deep gold seams.

Step 2: Tunnel Development

Horizontal tunnels (drives) are built to reach the gold reef.

Step 3: Stoping

Miners cut out the gold-bearing rock using drilling and blasting techniques.

Step 4: Haulage and Lifting

Involves rock transportation via underground rail or conveyor systems and lifting to the surface using massive hoisting systems.

This method is labor-intensive and expensive, with challenges like high temperatures and seismic activity.

3. Open-Pit Mining – For Near-Surface Deposits

Open-pit mining employment occurs when the gold deposits occur closer to the ground surface. This involves:

- Removing layers of soil and rock to expose the ore body

- Using large trucks and excavators to haul the ore

- Employing heap leaching or crushing and milling to extract the gold

Open-pit mining is more cost-effective than deep underground operations but is only viable for shallow deposits.

4. Processing the Ore

Once the gold-bearing rock is brought to the surface, it undergoes several stages of processing:

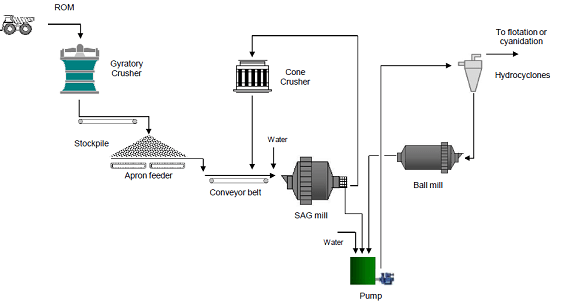

Step 1: Crushing and Grinding

Crushing the ore to fine particles releases the gold.

Step 2: Gravity Separation

Heavy gold particles become separated from waste rock using gravity-based methods.

Step 3: Cyanide Leaching

Gold becomes dissolved using a diluted cyanide solution in a process known as carbon-in-leach (CIL) or carbon-in-pulp (CIP).

Step 4: Electrowinning and Smelting

Gold, now recovered from the solution, becomes melted into bars or poured into molds.

5. Tailings and Environmental Management

After processing, leftover material—called tailings—stored in tailings dams. Modern mining companies are required to:

- Monitor water contamination risks

- Implement dust and erosion control

- Rehabilitate mined land after operations end

Environmental regulations have become stricter in recent years to reduce the impact of mining on communities and ecosystems.

Frequently Asked Questions (FAQs)

Q: What method is mostly used to mine gold in South Africa?

A: Deep-level underground mining is the most common method, especially in the Witwatersrand Basin.

Q: How deep do gold mines go in South Africa?

A: Some mines reach depths of over 4 kilometers, making them among the deepest in the world.

Q: Does gold mining still happen in South Africa today?

A: Yes, although production has declined due to aging mines and rising costs, companies like Sibanye-Stillwater, Harmony Gold, and AngloGold Ashanti continue active operations.

Conclusion

Gold mining in South Africa remains a major industrial activity, relying primarily on deep underground mining in the Witwatersrand Basin. Despite increasing technical and economic challenges, the country continues to play a key role in global gold production through advanced extraction and processing methods.